- Free Parking

- Sailing through nature

- 100% Self-sufficient

foto: Paul van Gaalen

Once upon a time, Giethoorn had twenty shipyards – small but flourishing artisanal businesses. The traditional oak boats, called “punter” in Dutch, were the workhorses of the village. Transport by water was very common. For transporting livestock, moving house, weddings and even funerals, the wooden boat played a prominent role due to its shallow draught.

Today there are only two shipyards left. The “Punterwerf Wildeboer” is one of them. Around 1890, Thomas Vos laid the foundations for the current shipyard. From a shed on Appensteeg, his crafted Giethoorn boats, rafts and barges found their way to farmers and traders.

Over the centuries, the shipyard passed from father to son or son in law. And not just the shipyard. The unsophisticated craftsmanship, the techniques, the feeling and love for the wooden boats were also passed down to generations. That love for the craft had to be unconditional. A passion, rooted in the genes. Since 1933, the oak boats have been made at the current site on Beulakerweg. Founder Vos’ great grandson Henk Wildeboer took over the business from his father in 1990. Together with his wife Yvonne, he embarked on a new course.

The old workplace with its black-tarred planks which seemed to be kept in place by cobwebs, is no more. On the waterside, a modern shipyard has been built. And a shop packed with boat accessories. The wooden boat builder has set out a new course to keep the old profession afloat. But the traditional atmosphere, craftsmanship and hospitality remain.

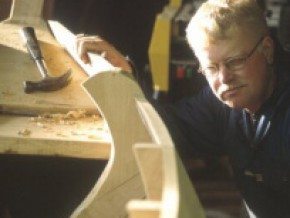

Nowadays, it is a shipyard of today with the feel of yesterday. In the workplace, you can actually smell the craftmanship: wood and tar. Boat builder Henk is comfortably doing what it needs to treat the wooden material. He trusts his intuition, his feeling and his patterns trained over the years. Clamps and molds. Underneath wood curls and chips a masterpiece of wooden art will arise.

A well-trained eye inspects the process.

You can see them spread out in the shipyard. Entire oak trees sawed into fist-thick planks. On shore as well as on the water. This is part of the century-old process. Fresh wood is not allowed. A traditional wooden boat owes its form to the combination of wet and dry, expansion and shrinkage. It all starts with the bottom. The plank in the middle is dry, the outer two have spent time in the water. When the boat is ready and is placed in the water, the dry centrepiece will expand until the hull of the wooden boat is watertight.

The curving of the sides is also the result of interaction with nature. Above the fire, one side of the plank dries and shrinks. The wooden boat builder sprinkles water on top of the other side so that the wood expands. Silently, he watches it happen. Weights assist him in his job. Surprisingly, there are no drawings. His grandfather’s jigs and a trained eye are his only guidelines.

And this is how the daily routine looks like for Henk and Yvonne Wildeboer at their yard in Giethoorn. True craftmanship in a modern yard, yet honouring the traditions: While the chimney stills smokes outside, Henk is diligently inspecting the gunwales inside the workshop. With some fine-tuning here and there, his work will be done. Yvonne is varnishing a boat at the back of the workplace, in six layers – just like it should be. As a result, the showpiece is bright and shiny for a long, long time.

Photos: Paul van Gaalen

You can reach us

from 9am to 5pm.

We speak English

+31 (0)521 36 1203

For general questions

You can contact us by

e-mail.

info@punterwerf.nl

Beulakerweg 48

8355 AJ Giethoorn

View on map